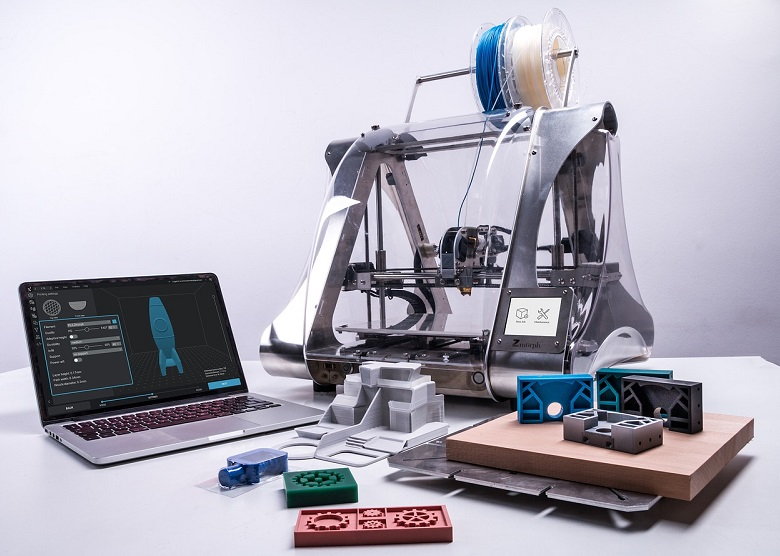

3D printing is the creation of a three-dimensional object from a printer. This process produces objects by layering material that corresponds to consecutive cross-sections of a 3D model. If you are interested in 3D printing but are not sure of the most cost-effective ways to do this, then you’ll want to continue reading. Here we break down why 3D printing can be so costly and how you can 3D print without breaking the bank.

Why Is It So Expensive?

Although they may appear new, they have been used by engineers and designers for over 30 years. It’s just that they only recently made their way to the public. This uptake in popularity is due to increased accessibility. 3D printing is so important because it can transform the way we consume products. By giving people the ability to build their goods in any way they like, there is a significant shift in manufacturing power. This technology will be around for a long time, and as time goes on, it will only get more refined.

3D printers can transform almost every industry from creating bespoke bone implants to printing airplane parts. These printers could even play a role in reducing plastic waste around the world; this could be part of the reason they are so expensive. However, it is also believed that at some point, every home will own a 3D printer to print whatever they need, revolutionizing the way we live and consume.

However, the high costs of these printers mean that this is not likely to happen for a long time. Purchasing a printer can be very expensive due to them being meticulously engineered and manufactured in limited numbers. Moreover, they can still be expensive due to the materials used. Filaments used in commercial printers are more experienced than commodity materials at the lower end of the spectrum. Whatever the material, plastic, metal, or glass, filaments need extra processing before they can be used.

Improvements also need to be made to the materials. Many printers use plastic as these melt easily and fit into small molds. However, they are unsuitable for many items, such as household products that have moving parts. For printers to be of the most beneficial to consumers and manufacturers, they would need to use carbon composites or metals.

Size

If you are a 3D print enthusiast but don’t want to pay an arm and a leg, there are some ways to make the process a little cheaper. Start with the size of your design. In this world, the size of your print makes a difference. Play around with the scaling to find a size that you like, but that will cost down the size of the print.

Get Searching

While 3D printers have become a lot more popular in recent years, they are still not too widely available. There are still affordable printers out there; you just need to look in the right places. There are certain things you should look out for when it comes to finding a printer. The folks at io3dprint.com recommend checking out the print quality before purchase. Check the layer resolution as this is a factor that will determine the print quality as well as the print volume. Ensure the printer’s specs are aligned with the needs of your designs and ideas.

Attach Non-Printed Parts to 3D Prints

It may seem odd but if you want to slash some cash, think about where you can use non-printed parts for the design. 3D printing is great for complex designs, customized models, or low-volume orders. Not all parts need to be 3D printed, instead, choose the most important parts and replace the parts that will get away with not being printed, such as tubes or metal rods. The more creative you can get here, the more money you can save.

Hollowing Out Your Design

An easy way to reduce the cost of your design is by hollowing it out; this way, you are using a lot less material, making it a lot cheaper. You will need to adjust your design manually, but cutting down the volume will make it much more cost-effective.

There are various ways to make 3D printing cheaper for you. Do your research on materials and printers to ensure you are getting the best bang for your buck. As exciting as it is, doesn’t leap at the first printer you find. Ensure you are informed of your purchase. If you have children at school, imagine the project models they could turn out.